How is a Horse Trailer Made [A Buyer's Complete Guide]

The manufacturing of a horse trailer is a meticulous orchestration of design, materials, and craftsmanship that culminates in a vehicle designed for the safe and comfortable transport of horses. It's where blueprints come to life, transforming raw materials into gleaming trailers that both riders and horses can trust.

Not understanding the manufacturing process puts you in danger of purchasing a trailer that requires expensive maintenance, or one that compromises safety and doesn't hold its value. Also, a horse trailer that doesn't comply with industry standards could result in legal issues or fines because it could be deemed unfit for use.

Join us in this expedition, navigating the twists and turns of horse trailer manufacturing: the rigorous quality controls, the set industry benchmarks, the latest innovations, strides in sustainability, the allure of materials, and the art of customization. Delve deep, and ensure your next horse trailer purchase is well-informed.

Key Stages of Horse Trailer Construction Every Buyer Should Understand

Constructing a horse trailer involves a blend of engineering expertise, hands-on experience, knowledge of the horse industry, and specialized production equipment. In this section, we will detail the 8 primary stages integral to the process as follows:

- Horse trailer design and planning

- Horse trailer material sourcing

- Frame construction

- Interior construction

- Wiring and plumbing

- Exterior construction

- Painting and finishing

- Quality control and inspection

1. Horse Trailer Design and Planning

The design and planning stage in horse trailer manufacturing involves creating a detailed blueprint. Considering factors such as size, weight capacity, and must-have specific features enhancing horse safety and comfort are crucial during this period.

Why is this stage important for a buyer to know?

Being informed about the design and planning process offers a buyer insights into the overall quality and craftsmanship of the horse trailer. It's a direct reflection of its potential durability, longevity, and safety features.

2. Horse Trailer Material Sourcing

Sourcing involves selecting materials that align with the desired specifications and performance criteria for the horse trailer, a process backed by research, planning, logistics, and efficient processing. Keep in mind that the choice of materials significantly impacts a trailer's safety, weight, comfort, and lifespan.

Why is this stage important for a buyer to know?

A buyer can make informed decisions about the trailer's suitability for their specific needs by comprehending the specifics of material choices—their attributes, applications, and benefits.

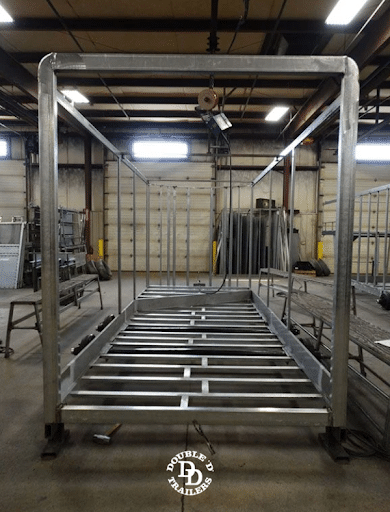

3. Frame Construction

The frame of a horse trailer is its foundational backbone. It must combine rigidity, flexibility, and lightness for optimal performance. The construction process encompasses 3D modeling, rigorous testing, precision cutting, welding, bonding, and comprehensive rust-proofing. Often, a jig is employed to facilitate various fabrication stages, including the axle installation.

Why is this stage important for a buyer to know?

Understanding the quality of a frame, from its materials to its production methods, empowers a buyer to confidently select a horse trailer that offers rust resistance, the right balance between rigidity and flexibility, low maintenance, and sufficient load-bearing capacity.

4. Interior Construction

Designing a horse trailer's interior involves meticulous layout planning, ensuring safety with wall insulation and padding, installing flooring, stall dividers, and integrating electrical and ventilation systems. Trailers with living quarters demand intricate planning due to extensive customization options.

Why is this stage important for a buyer to know?

Being well-versed in interior construction allows a buyer to discern which interior configurations best suit their requirements. It also provides clarity on the features to prioritize when purchasing or customizing a trailer.

5. Wiring and Plumbing

The electrical and plumbing systems in a horse trailer are tailored to its specific blueprint. Careful positioning and setup are required for cable harnesses, switches, light fixtures, insulation, water tubing, drains, and storage tanks, among others.

Why is this stage important for a buyer to know?

A buyer who is aware of proper electrical and plumbing setups can identify potential issues in a trailer. This awareness also equips a buyer with knowledge about the range of available features, ensuring they - and their horses - benefit from all safety enhancements.

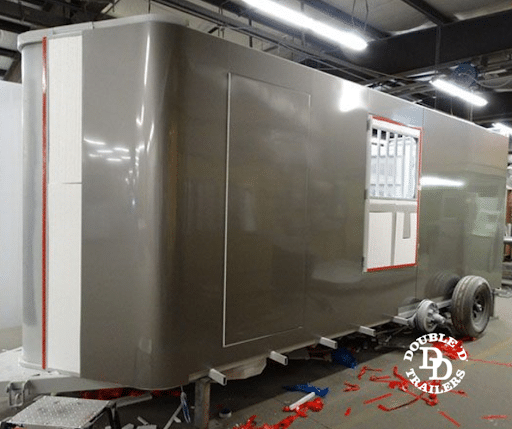

6. Exterior Construction

The exterior construction of a horse trailer is a meticulous process that involves crafting a robust yet lightweight shell, meticulously designed for thermal insulation. Materials like steel, aluminum, and advanced composites are handpicked for their durability and insulating properties. From there, elements such as the roof, walls, doors, and ramps are seamlessly integrated into a carefully crafted metal frame. This dedication to precision ensures that every journey is both safe and comfortable for your horse.

Why is this stage important for a buyer to know?

Grasping the exterior construction process empowers a buyer to identify the best material combination, ensuring a balance of safety, durability, thermal insulation, noise control, and longevity.

7. Painting and Finishing

Final touches on a horse trailer involve protective coatings, painting, decorative elements, window tinting, and adding exterior fixtures like moldings, trims, lights, and accessories.

Why is this stage important for a buyer to know?

Knowing what the painting and finishing processes involve allows a buyer to distinguish quality trailers easily and opt for a manufacturer that offers the type of finish they prefer. A quality finish is usually a sign of advanced craftsmanship, and any buyer should settle for no less.

8. Quality Control and Inspection

Upon completion, each trailer undergoes a rigorous inspection to assure build quality and identify any areas requiring refinement. This control process tests all onboard systems, checks crucial frame components, doors, ramps, couplings, and more.

Why is this stage important for a buyer to know?

Awareness of thorough quality control processes assures a buyer of the safety and functionality of their trailers. Moreover, it readies the buyer for similar evaluations when considering used horse trailers.

Why Should Buyers Know the Different Stages of Horse Trailer Construction?

Familiarity with the step-by-step manufacturing process of a horse trailer results in the following:

Proper Understanding of Product Quality

Recognizing the quality of a horse trailer ensures buyers uphold stringent standards, facilitating the selection of finely crafted trailers.

Informed Buying Decisions

Grasping the comprehensive construction process empowers buyers to discern potential defects and guarantees robust, uncompromised trailer choices.

Smart Customization Requests

Awareness of the construction nuances allows buyers to specify desired custom features, ensuring the final product aligns perfectly with their needs.

Realistic Budgeting

A comprehensive understanding of construction intricacies, material choices, and design options positions buyers to allocate budgets judiciously, securing maximum value.

Clear Communication with Manufacturers

Armed with knowledge, buyers can efficiently engage manufacturers, detailing precise trailer specifications and comparing bespoke offers swiftly.

Accurate Troubleshooting and Maintenance

Post-purchase, a well-informed owner can swiftly identify potential issues and ensure thorough and effective maintenance.

Quality Assurance in Horse Trailer Manufacturing

Quality assurance (QA) stands for extended monitoring, documenting, and other activities designed to ensure that the quality of a particular production process (and the finished products, for that matter), such as horse trailer manufacturing, is as expected. Quality assurance also guarantees compliance with all relevant requirements and standards, helps boost customer satisfaction, and reinforces the manufacturer’s reputation.

The four main stages of quality assurance in horse trailer construction include:

- 1. Planning: The foundation of QA lies in the project design, ensuring it aligns with all prevailing industry and regulatory standards.

- 2. Implementing: This involves ensuring all the selected materials and planned fabrication steps comply with the necessary criteria.

- 3. Checking: This phase involves a meticulous inspection and rigorous testing of the completed product.

- 4. Adjusting: Any aspect of the trailer's fabrication process that may require fine-tuning is addressed to get final approval.

Best Practices and Methods for Quality Assurance

There are dozens of typical methods for quality assurance, but a handful of them matter the most, as follows:

- Benchmarking: This involves comparing products or processes with industry leaders to set a new quality benchmark.

- Business Process Re-engineering (BPR): BPR seeks to refine existing processes within a business to enhance quality, reduce costs, and improve efficiency.

- Cost-Benefit Analysis: This method evaluates the balance between the efforts to achieve quality and the related expenses.

Examples of Quality Assurance in Manufacturing

A standard operating procedure (SOP) is a prevalent QA method in manufacturing, minimizing errors and inconsistencies in quality. Another example of quality assurance in manufacturing is monitoring machine performance and live data. This prevents production and assembly hiccups because it shows potential restricted performance and thus allows for preliminary maintenance and fault detection.

Key Performance Indicators for Quality Assurance

Key performance indicators (KPIs) are among the best QA practices in manufacturing because they assist long-term business goals and decision-making. Effective KPIs should:

- Provide value

- Allow for easy measurement

- Support all company goals

The most important KPIs to implement are as follows:

- Acceptable delivery speed: All products should be delivered within preliminary set terms based on the order cycle design

- Low defect rate: Product defects should be non-existent or kept within the allowed percentage

- Production schedule attainment: Production temp and efficiency should be as planned and according to company benchmarks

Quality Assurance Vs. Quality Control

Quality assurance and quality control are not the same thing. While quality assurance is part of the design and construction processes from the get-go and aims to guarantee an excellent result, quality control only comes into play to confirm the achieved excellence, once the product is finished and precedes its delivery to the client.

How to Check for a Manufacturer's Quality Assurance Processes: 10 Tips and Pointers

When you’re comparing horse trailer manufacturers, it’s relatively easy to determine if either of them has implemented quality assurance processes to guarantee excellent product quality. Here are 10 tips to help you identify a horse trailer manufacturer’s QA efforts.

1. Verify Certifications

A manufacturer's association with reputable organizations like ISO (International Organization for Standardization) or NATM (National Association of Trailer Manufacturers) signifies adherence to high-quality assurance standards.

2. Ask About Their Quality Assurance Processes

In some cases, there isn’t a clear indication of any QA policies or certifications, so you should send an inquiry regarding the company’s current quality assurance standards.

3. Request to See Their Inspection Reports

Quality assurance comprises several monitoring and documenting processes, meaning that there should be plenty of stored information (inspection reports and analyses) you could ask to check out. Systemized information in the form of a report will always give you the answers to all QA-related questions.

4. Look for Consistency

Quality in manufacturing is not something achieved overnight. A horse trailer manufacturer should make a consistent effort to provide and monitor it, which is something you can easily differentiate when comparing different companies.

5. Gauge Staff Expertise

Given the craftsmanship intrinsic to horse trailer manufacturing, evaluating the expertise and training of the staff is prudent. This assessment can illuminate whether the team crafting your trailer is aptly skilled.

6. Ask About Their Equipment Maintenance Practices

As a potential customer, you have every right to ask a horse trailer manufacturer about the maintenance frequency of the machinery they use. Most such businesses would be glad to introduce you to this part of the fabrication cycle.

7. Observe Their Response to Defects

It’s always a good idea to try and find information regarding how a particular horse trailer manufacturer handles product defects. Except for the extent of the factory warranty, you should try to find out if recurring defects always lead to adjustments in the supply and fabrication processes or not.

8. Look at Their Product Reviews

Client feedback always matters, and browsing through product reviews is the best way to see what current clients of the horse trailer manufacturer you’re researching think about their horse trailers. If positive feedback prevails, then you can continue your research.

9. Consider Their Communication

One of the most underestimated signs of whether you should choose to work with a particular horse trailer manufacturer is the way they communicate with their existing and future clients. If there are issues related to communication, then the whole process of ordering a new custom trailer could be tedious or even flawed.

10. Check for Continuous Improvement

A trustworthy horse trailer manufacturer should follow a constant learning curve. There’s nothing wrong with tradition, but true success comes when a company embraces new technology and materials and combines it with its amassed experience. This is what improvement looks like.

How Does the Manufacturing Process Contribute to a Horse Trailer's Value?

The quality of a horse trailer fabrication process determines the quality of the finished product, therefore, it affects its price and also its resale value. Quality-built trailers that meet the highest safety standards and bring the ultimate comfort for both horses and humans are almost always more expensive than other rigs, but the heftier price tag is justified by the trailer’s longer-retained value.

Advancements in Horse Trailer Manufacturing: A Glimpse Into the Future

Recent breakthroughs in horse trailer manufacturing have transformed the industry, introducing enhanced safety features, extended product lifespans, a diverse range of production materials, and a plethora of custom features and optional equipment. As a leader in this evolution, Double D Trailers exemplifies this commitment to progress. With Double D Trailers being built with safety as the cornerstone, our patented SafeTack design stands as a testament to our unwavering dedication. We seamlessly merge time-honored traditions with forward-thinking innovations, ensuring our trailers meet the highest safety standards.

Pioneering the Change: The SafeTack Design

The SafeTack design revolutionized the industry thanks to a simple, yet important innovation. Typically, loading or unloading horses from the back of a slant load horse trailer is not the easiest task because the tack area obstructs access in both directions. The SafeTack solution comprises a swing-out tack compartment that completely removes obstacles from the back, thus allowing horses to be loaded or unloaded effortlessly.

Keeping a Tab: Tire Pressure Monitoring System (TPMS)

Tire pressure monitoring systems (TPMS) are essential for safety in the automotive world. Thanks to sensors mounted on the rim, this system constantly monitors the air pressure inside every individual tire. This allows for early warning in case of a puncture, thus preventing major accidents.

Trailers with a Tech Edge: GPS Tracking System

GPS tracking systems have been around for quite some time, but they were only introduced to the horse trailer industry not too long ago. GPS trackers allow for precise positioning of the trailer in real-time thanks to satellite connection. This helps when a trailer needs to be located after a distress signal, a reported accident, or in case of theft.

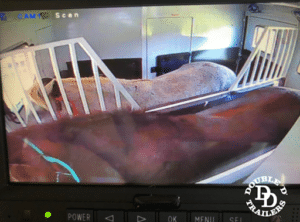

An Insightful Journey: Wireless Camera Monitors

Monitoring horses during transportation is crucial for their safety and comfort. Thanks to wireless cameras mounted inside the horse area and monitors placed in the tow vehicle, you can constantly keep an eye on your horses and watch for possible erratic behavior or other issues.

>> READ OUR REVIEW OF TOP HORSE TRAILER CAMERAS

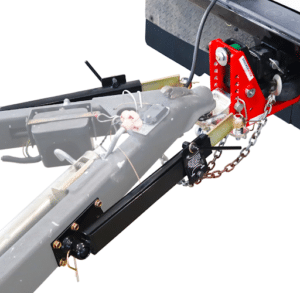

Navigating Tough Terrains: AirRide Gooseneck Hitch

An AirRide gooseneck hitch replaces a regular gooseneck coupler and pin and is intended to provide a smoother towing experience. AirRide is a safe alternative that also protects both horse trailers and tow trucks from excessive wear and stress by allowing them to handle bumps and tension more easily.

Breathing Easy: The Flettner Ventilator

Flettner ventilators’ clever structure allows them to replace hot and dense stall air with fresh outside air. Having such ventilation is a must, as it not only cools down the horse area but also extracts potentially hazardous fumes accumulated inside. The Flettner rotor design has been around for more than a century.

Shading in Style: Smart Arm Awning

Smart Arm awning kits provide a fully automated awning feature, thus providing plenty of convenience and comfort. Unlike manually operated awnings, Smart Arm kits feature a waterproof controller that allows for easy operation. These features save time and effort.

The flourishing innovations and technological integrations in horse trailer manufacturing stand testament to an industry committed to continual evolution, ensuring equine safety, owner convenience, and long-lasting value.

Embracing Sustainability in Horse Trailer Manufacturing

Composites have gained moderate popularity in recent years, but the industry is still transitioning to primarily using sustainable materials like carbon fiber and polycarbonate. If you’re wondering how to buy a horse trailer that aligns with sustainability, Double D Trailers leads the way. As the industry pioneer in sustainable horse trailer manufacturing, Double D Trailers is set to revolutionize the market with its upcoming 3D-printed horse trailer lineup.

The Future is 3D: A Dive into 3D Printing Technology

The SafeTack Reverse 2 Horse Bumper Pull Carbon is the first of its kind: a fully 3D-printed horse trailer that’s all about sustainability in horse trailer fabrication. This model not only boasts a faster and more eco-friendly production process but also champions materials like polycarbonate, carbon fiber, and fiberglass. Such materials are durable and recyclable and outshine traditional materials like steel and aluminum in terms of environmental impact. Furthermore, this trailer highlights enhanced durability, a longer lifespan, and a significant weight reduction compared to its conventional counterparts.

Learn More About Pre-Ordering the SafeTack Reverse Carbon

The Anatomy of Horse Trailers: Materials and Components

Traditional horse trailer materials include alloy steel, aluminum, and composites. More advanced materials also exist, such as Double D Trailers’ patented Z-Frame technology and the latest innovation, the 3D-printed technology comprising fiberglass, carbon fiber, and polycarbonate.

The primary components of a horse trailer include its frame, axles, wheels, coupler, shell, interior and exterior walls, roof, doors, windows, tack and dressing rooms, living quarters, and loading ramps.

The Traditional Trio: Most Common Horse Trailer Materials

Alloys, steel, and aluminum are the most popular horse trailer manufacturing materials. All-aluminum horse trailers exist, but they are not as rigid as steel ones. The latter, however, are prone to rust, not to mention they are typically way heavier. Combining steel and aluminum is a common practice that results in improved weight and better longevity.

Treading the Green Path: Sustainable Horse Trailer Materials

Choosing proper horse trailer materials extends beyond mere functionality. Opting for sustainable materials not only benefits the environment but also promises longevity, reduced weight, and aesthetic appeal for the trailer.

Unveiling the Exterior: Key Horse Trailer Exterior Components

The main horse trailer exterior parts are the frame, the shell structure, and the hitch, which are usually made of steel alloy. The exterior walls and roof can also be steel-made, but they’re often either aluminum, composite or a combination of these materials. Fiberglass is lighter and stronger than aluminum, and it conducts less heat, making it a good choice for roof material.

Inside the Cocoon: Delving into Horse Trailer Interior Components

The interior of a horse trailer comprises inside walls and padding, horse stall dividers, a dressing room, a tack room, living quarters, flooring, ramps, and doors. All of them should be carefully selected and combined with one another to ensure safety, comfort, and longevity.

Get the Best Bang for Your Buck: Know Your Horse Trailer Inside Out

As a horse trailer buyer, knowing all about horse trailer manufacturing will always give you an array of advantages. When you learn how every step of this complicated process works and what it takes to be completed, you will know what to opt for and what to steer away from in terms of quality, materials, practicality, value, and longevity. You will also be able to recognize and demand specific materials, technical specifications, and custom options.

Understanding horse trailer fabrication in detail will allow you to make the ultimate choice by easily comparing various manufacturers and models. Armed with this knowledge, why not take the next step? Order a custom horse trailer tailored to your needs, ensuring top value, adherence to industry standards, and uncompromised safety.