Z-Frame: A Safer Option Than Aluminum Horse Trailers

Frustrated with a rusty horse trailer causing constant repairs and safety concerns? Z-Frame technology is Double D Trailers' revolutionary approach to trailer construction that combines strength and corrosion resistance. Unlike traditional trailers, Z-Frame's zinc-infused tubing is ultra-strong and rust-proof, ensuring maximum safety and comfort for your horses.

What Has Changed in Trailer Construction?

Since the creation of the first modern horse trailers in the late 1950s, manufacturers have been stuck between a rock and a hard place when it comes to materials and building methods – constantly seeking the best way to build the ultimate horse trailer.

In the past, horse owners didn’t have many options when it came to buying a horse trailer. Most were made of unreliable materials that rusted easily and didn't last. The 1980s brought a new player: aluminum trailers. These trailers offered a lightweight, shiny, and clean design, but they had their own set of problems. Despite being lightweight, aluminum conducted a lot of heat, often leading to overheated and suffering horses in the summer sun. As technology has advanced, trailer manufacturers have strived to create trailers that are both safer and longer-lasting.

The first horse trailers looked pretty different from the trailers we’re familiar with today. They were a rusty welded combination of angled iron, bare sheet metal, and processed steel. Manufacturers welded the different pieces of metal together then primed and painted the trailer. And then they sent it off – ready to be sold. However, the poor choice of metal and the weakly welded joints quickly oxidized and pretty soon the brand-new trailer was covered in red rust.

Obviously, the lack of durability and the extreme rust was a problem. But back then, welding was the only option if you wanted to put together a piece of steel tubing and a piece of steel sheet metal. And there was no way to seal off moisture from getting between the two metals – that’s why those early constructions were so prone to rust damage.

Once trailer manufacturers realized that welding sheet metal and steel together just wasn’t going to work, they tried to come up with new technologies that wouldn’t rust as easily. Where did they turn to? Aluminum.

In the 1980’s, trailer manufacturers started using aluminum. At first – it seemed perfect. It was rust-proof, shiny, and nice-looking. And, since aluminum was so expensive compared to steel, most people believed that it must be better. Higher price, better quality, right? Well, not really.

But Were Aluminum Trailers Really Better?

But that wasn’t the case. Compared to the steel trailers of the 50s, the new aluminum trailers were not as strong or durable – and they even had some dangerous safety hazards. But that didn’t stop trailer manufacturers from making them and selling them to unsuspecting customers.

Brad Heath, owner of Double D Trailers, explained that “large horse trailer companies were quick to jump on the aluminum trailer bandwagon – they began to promote aluminum as a lightweight, non-rusting option compared to steel that was heavy and rust-prone.”

Today, many of those trailer manufacturers still continue to produce aluminum trailers – because they’re in too deep to back out and change construction materials and designs. But that doesn’t mean that aluminum trailers are your best option.

Steel trailers are still much safer than aluminum trailers. Trailers with steel frames are durable, very safe, and – combined with today’s modern technologies – much better than the first steel trailer prototypes of the fifties.

Brad even says that “steel trailers are certainly a preference of mine in comparison to an aluminum chassis.” And, with the major advancements that the construction industry has seen in recent years, new construction methods have given horse owners even more options for horse trailers. Now, there’s a safer and better option than steel…

It’s called Z-Frame -- but more on that later!

The Worst Material for Trailers and Why

Although aluminum trailers do a fantastic job resisting rust, and looking great for years and years, there are many important drawbacks and dangers that anyone looking for a horse trailer needs to be aware of.

Aluminum Trailers Can Reach Inside Temperatures of 130 – Or More!

Aluminum Trailers Can Reach Inside Temperatures of 130 – Or More!

First, aluminum trailers are incredible heat conductors. And when the entire roof of your trailer is made of this superconductive material, and the sun is beating down on a summer afternoon, you can literally feel the heat radiating off the metal walls and ceiling and heating up the trailer.

That means inside an aluminum trailer, it can get really hot, really fast. Temperatures can reach up to 130 degrees Fahrenheit – way too hot for your horse. In fact, such extreme heat is really dangerous for your horse – leading to extreme sweating, dehydration, and other health problems.

Aluminum Trailers Have Unsafe Metal Floors

Another hidden danger of aluminum trailers is their metal floors. Although most are covered by rubber mats, the metal bottom still can cause problems for your horse. First of all, it increases the heat transfer up from the hot roadway directly to your horse’s legs. Not to mention the additional vibration and noise that lack of insulation causes as well – both things that can make your horse nervous and uncomfortable.

It’s also important to note that metal floors are prone to corrosion. Since horse urine is very acidic, it can add to the wear-and-tear corrosion and slowly weaken the metal floor in an aluminum trailer – making every trip more and more dangerous.

When the trailer floors are corroded and weak, you put your horse in danger of full floor failure – meaning that your horse’s hoof could punch through the weakened metal floor down to the roadway while your trailer is in motion.

Obviously, this is extremely dangerous and scary for your horse, especially during travel. Most horses involved in horse trailer accidents like these are fatally injured and must be euthanized immediately. That’s what makes metal floors so dangerous. And even when those floors are covered with synthetic coatings, there is still a danger of corrosion and accidents.

Aluminum is a Weak and Flimsy Material – and It’s Terrible for Safety

The dividers inside of an aluminum trailer are especially dangerous to your horses. When a nervous or panicked horse starts to move around near the aluminum dividers, they twist and tear, exposing the sharp pieces of metal that can then injure your already anxious horse.

And, in the case of an accident, aluminum is the worst material for your trailer to be made of.

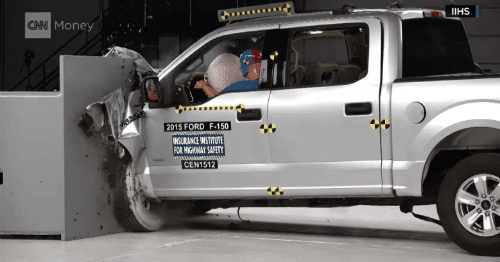

Just Take a Look at These Terrible Crash Tests for the 2015 All-Aluminum Ford F-150

A few years ago, Ford decided that they were going to make an all-aluminum pick-up truck. It was called the Ford F-150 SuperCab truck. When Brad Health found out about this new experimental truck, he was immediately interested. For years, Brad had been telling everyone about the dangers of building vehicles out of aluminum. He knew that aluminum, although it’s lightweight and rust-resistant, is an extremely dangerous material choice.

Unfortunately, Ford had to figure that out the hard way – after spending time and money creating their all-aluminum truck. Ford decided to test the safety of their new truck in July 2015, when the new Ford F-150 SuperCab truck was sent to do a ‘small overlap front crash test.’ This type of crash test is when a vehicle slams into a barrier going 40 mph with just a small fraction of the driver’s side front bumper. This is one of the most common and most effective crash tests because 25% of all serious and fatal injuries from front crashes happen because of ‘small overlap’ mistakes like these.

During the crash test, the entire front end of the truck flattened into the barrier like a soda can. The passenger side of the truck was crushed. Parts of the lower area of the truck, including the footwell, were pushed backward almost a foot, creating a high risk of foot and leg injuries. Ford’s SuperCab truck was given the second-worst rating after observers saw how it performed.

Needless to say, Ford had to go back to the drawing board and significantly increase the thickness of the aluminum they were using in their trucks in order to meet safety standards.

When Brad saw the results, he wasn’t surprised. He said, “Aluminum is just not cut out for high-stress situations, and it just can’t take the same abuse as steel is able to.” Since there aren’t crash tests for horse trailers, the Ford crash test was an important and telling moment for all aluminum vehicles and trailers, revealing the truth about how unsafe that material really is for transportation.

Although many manufacturers continue to use aluminum, covering up how dangerous it is with complex marketing schemes and cheap price tags, it doesn’t change the fact that aluminum is simply not the right material for trailer construction.

What about Steel Horse Trailers?

Many consumers are attracted to the lower costs of steel trailers and their strong designs. Many horse owners purchase steel trailers, wanting a trailer that will be safer for them and their horses. There are three main options for steel trailers on the market today:

1. All-Steel Trailers

All-steel trailers tend to be more affordable than other styles of trailers – mainly because they are cheaper to produce. They usually have an older style but have a strong frame and design. To make them, trailer manufacturers take cold rolled sheet metal and weld it together, then paint over it. The low labor costs make it affordable to produce.

The downfall, however, is that the thin steel sheets have a tendency to rust in the welds and seams. Depending on where you live and what the climate is like, these trailers can rust out in a matter of years. But it is important to note that with new technologies, especially the modern bonding techniques most manufacturers use today, steel trailers today last longer than their earlier prototypes.

2. Aluminum Skin Trailers with a Steel Frame

Brands like Calico are known for their all-steel trailers, while brands like Merhow and Adam have adopted a different construction style – a steel frame with aluminum skin. This is a common way to build trailers, and since there are different metals being used – there’s a lot of parts to assemble.

Normally, manufacturers start with the steel frame – they prime and paint it and make sure it’s all ready to go. Then, the thin aluminum sheets are attached one by one to the metal frame. Usually, manufacturers use non-mechanical fasteners instead of welding so that the trailer is more durable and less vulnerable to weathering.

The result – a very durable trailer. But it will end up costing you about the same amount as an aluminum-frame trailer or an all-steel trailer.

3. Galvanneal Skin Trailers with a Steel Frame

That’s why, if you happen to find an older Double D Trailers model that has a Galvanneal Skin, you’ll find that it’s still in pretty great shape. Galvanized steel is made specifically to last longer and to not rust, creating a super durable product that will last you years and years.

Z-Frame: The Latest and Most Modern Trailer Building Technology

Around 2009, Brad began looking for a better option. He knew he didn’t want to make trailers out of aluminum – it was too weak and not at all safe. And he knew that steel, although it was strong, rusted easily. He had been using Galvanized steel for certain parts of the trailer but wanted to find a better way.

He needed to find a way to create a trailer that was as strong as a steel trailer but one that would stay rust-free like an aluminum trailer. There had to be the perfect material that was super strong, easy to work with, very lightweight, and didn’t rust. What was the solution?

The solution was developing their own exclusive Z-Frame Technology – a new type of material that was perfect for horse trailers.

What is Z-Frame Technology?

The Z-Frame tubes are made by infusing a steel base with zinc and chromate – two metals that come together to resist oxidation and reduce road heat transmission. This zinc-chromate-infused alloy is then made into tubes, which are used to create the durable and strong frame for your Double D trailer.

Truly, Z-Frame is the latest in horse trailer expertise – the zinc and chromate metal combination is extremely strong but at the same time, very lightweight. Starting with the Z-Frame creates a reliable, safe, and durable foundation to then complete the rest of your trailer.

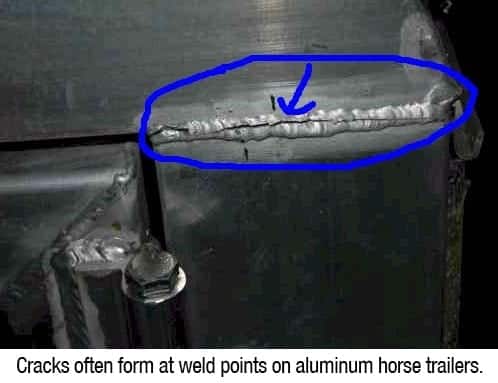

Z-Frame is simply the safest construction method for a horse trailer. Brad says, “The whole process behind our exclusive technology actually increases the tensile rating of the tubing – making it so much stronger than aluminum. And, it eliminates the issue of ‘cracking’ in the welds, something that happens with aluminum materials over the years.”

What’s the Wall System Like?

After the Z-Frame is built on a Double D trailer, it’s time to add the walls. To make sure the trailer is both beautiful and long-lasting, we use a double-insulated wall system. The walls are made of Galvalite skin and chemical 3M bonding – creating a barrier that keeps out air and moisture and keeps your horse at the right temperature. And, there are no rivets, bolts, or screws in the wall design – since all small pieces are vulnerable to weathering, we’ve created a way to secure your trailer skin to the Z-Frame without them, making your trailer more durable and robust.

It’s actually very important not to use rivets or screws on the sides of your horse trailer. Why? Because the temperature outside and inside your trailer is constantly changing. And this change in temperature causes the metal walls to expand and contract. If you have screws holding together the walls, the metal is restricted from moving freely, creating wavy sides and sheet warpage.

The 3M bonding technology in Double D trailers allows the Galvalite skin walls to “breathe freely” because it doesn’t require a single screw or fastener (see below for more details). And, although the Galvalite skin looks very similar to aluminum, it’s actually 5 times stronger than aluminum. That means you’ll have fewer problems down the road – and, in the case of an accident, your horse will be much more protected.

Paints and Sealants on a Z-Frame Trailer

Ever since the 1950s, primers and chemical coatings have made steady improvements in horse trailer manufacturing. The latest methods used by Double D Trailers involve a technology from 3M called VHB. We use VHB technology to attach the exterior skin to the frame of the trailer.

It is often referred to as “tape” because it comes in a roll and is tacky to the touch. In reality, the word tape really doesn’t do the bonding justice. That’s because the bonding property between the two metals is actually much stronger than a traditional weld.

Not only is it stronger, it’s also watertight and remains pliable – which cuts down on noise and vibration. This pliable property also allows expansion and contraction of the trailer’s materials which reduces warping and extends the life of the trailer.

So really, this 3M chemical bonding process isn’t tape, but rather a chemical bonding process that seals the two metals together. It’s the best our industry has to offer!

The SafeBump Roof Protects Your Horse

The roof of your trailer is a one-piece SafeBump roof. Since it’s all one piece, it’s 100% leak-proof, which not just keeps your horse dry and happy, but also preserves the inside of your trailer, making it last even longer. The roof material is made of a fiber composite, which conducts heat much less than a mill-finished aluminum roof that absorbs the sun’s rays.

The SafeBump Roof material is flexible yet durable. That means, in the event that your horse gets spooked and rears up into the top of your trailer, the SafeBump Roof will actually absorb the impact of the collision, making it easier on your horse’s head and reducing the risk of injury.

The Floor Materials

Both the roof materials and the floor materials work together to minimize heat transfer from the road and the sun to the horse trailer. The floors are made of synthetic Rumber or treated lumber flooring – both materials that reduce vibration from the road and minimize noise – making traveling in your horse trailer much more enjoyable – and safer – for your horse.

Top 3 Reasons Why Your Next Horse Trailer Needs Z-Frame Technology

Double D Trailers focuses on creating the safest trailer for the best value for horse owners. That’s why we created Z-Frame Technology – it’s simply the most reliable and durable way to construct a trailer. And, with top safety features and unfailing construction methods, Double D Trailers are truly unique.

It’s no surprise that Brad often says, “Z-Frame is an awesome technology that every horse trailer manufacturer in the US should be using.” Z-Frame is the base of your trailer – it’s the foundation for everything else, which is why it’s so important.

1. Z-Frame Trailers Are Stronger and More Reliable

Because of the unique construction of the Z-Frame tubes makes them stronger than regular steel. You might be thinking that because the metal is stronger, it must be heavier. But actually, Z-Frame is both strong and lightweight. How? Because the zinc alloy is so strong, we can use smaller gauge metals that are just as strong as steel without the excess weight.

In fact, when we compared an all-aluminum two-horse bumper pull trailer with a dressing room to an almost identical Z-Frame two-horse bumper pull trailer with a dressing room, there was only an 80-pound difference!

And, the 99.99% pure zinc alloy isn’t just strong, it’s also extremely durable – providing you a trailer that you can trust and rely on for years and years. A Z-Frame trailer is going to perform better and last longer than older-style aluminum trailers and steel-built trailers.

2. Technology and Materials That Resists Corrosion

As a metal, zinc is one of the best options for avoiding rust and corrosion. You can find zinc in all sorts of different everyday objects. For example, most highway signposts, metal building structures, and bridge rails are all made of zinc. Take a stop sign for example. It needs to be able to withstand the effects of rain, snow, hail, and extreme heat without corroding.

Just like a stop sign, Z-Frame also uses zinc because it resists weathering – but Z-Frame is more advanced and even goes beyond that. The zinc-chromate combination has a much lower level of harmful lead content than normal pre-galvanized or hot-dipped products.

Z-Frame also resists salt corrosion better than typical zinc-based materials or other metals. Compared to something like a stop sign post, Z-Frame lasts up to 3 times longer in a typical salt spray test. So, you won’t need to worry about salt in the winter destroying the bottom supports on your horse trailer. Z-Frame has got you covered.

3. Better Temperature Control That Keeps Your Horse Comfortable and Safe

If you’ve ever stepped inside an all-aluminum horse trailer on a hot day, you know that aluminum lacks any type of temperature control. The heat from the sun just radiates down from the ceiling and heats up the horse trailer like an oven. Obviously, that’s not safe for your horses, and it can actually lead to dehydration and overheating.

The roof materials also make a big difference in the inside temperature of your horse trailer. The SafeBump roof that sits atop the Z-Frame is made of a fiber composite. It’s made of fiberglass, so it’s both self-insulating and much more weather-resistant than other materials. It’s also white, which allows it to reflect more heat than any other color. That reduces the amount of heat that’s transferred to your horse while they’re in the trailer.

Z-Frame Trailers Are the Safest Trailers for You and Your Horse

The frame of your horse trailer is the main structure that will protect your horse in the case of an accident. If you want your horse to be safe and secure while you are traveling, and protecting in the event of disaster, you need a strong frame that will shield and protect your horse.

An aluminum frame will rip and twist under force – this brittle metal will not have the strength to protect your horse in the case of an accident. A Z-Frame, however, is like a strong, durable, and protective frame that won’t crumple like a soda can under pressure. It’s simply the best way to safely transport your horses.

Only the best materials and the most advanced technology will protect your horse from potential dangers on the road. Any other trailers that take shortcuts during construction or use cheap materials are making manufacturing decisions that, while they might save you money today, will compromise you and your horse’s safety in the future.

Brad explains, “In this industry, you get what you pay for. A less expensive trailer might be good for your wallet, but it will result in ‘less’ of a trailer for sure.” When it comes to your safety and your horse’s well-being, it’s just better not to compromise.

With a Z-Frame trailer, you are getting a trailer with a strong foundation and a reliable base structure. It’s like building a house – first, you need to establish a strong foundation before building the rest of the floors and rooms. A Z-Frame is that reliable and sure base frame for your trailer. It gives your trailer a protective, light-weight, reliable and long-lasting trailer structure that will keep your horses safe during transit.

What Do Customers Say About Z-Frame Technology?

“As a firefighter, I had an opportunity to attend a 3-day large animal rescue class. After seeing what an accident can do to an aluminum trailer, we thought it might be a good time to look at getting rid of the aluminum trailer. We started an extensive Internet search and all paths led us to Double D Trailers, where we proceeded to order a 2 Horse SafeTack Reverse Living Quarters Trailer. We were very impressed with the thought and planning that went into a Double D Trailer, and we were particularly impressed with the Z-Frame®️ and the SafeBump®️ roof system.”

And the Z-Frame wasn’t the only feature that impressed Mike. He said that the temperature control in the new Double D Trailer was much better than his old one – “Even sitting out in the 100-degree Carolina sun, the interior stays much more comfortable compared to our previous metal roofed trailer.”

If you’re like Mike and feel that your horse’s safety is what’s most important to you when searching for a horse trailer, a Z-Frame is the best way to go. You can read the rest of Mike’s story below.

As you can see, a Z-Frame trailer has all the benefits of a steel trailer, and all the benefits of an aluminum trailer, without any of their weaknesses. All Double D Trailers are built with the protective and reliable Z-Frame, and they’re also all customizable, so you can help us design the perfect trailer for you and your horse.

Feel free to contact us if you have any questions about Z-Frame technology or creating a custom horse trailer.

Schedule Your Free Video Consult Today!

Aluminum Trailers Can Reach Inside Temperatures of 130 – Or More!

Aluminum Trailers Can Reach Inside Temperatures of 130 – Or More!